The engine room of a cruise ship is usually situated in the lower levels and stretches across multiple decks, covering a vast area comparable to several basketball courts. This complex and expansive space is responsible for driving the incredible engineering marvels that cruise ships are.

Understanding the layout of a cruise ship is essential to comprehend the significance of the engine room. This vital area serves as the heart and soul of the ship, housing the powerful engines that propel it through the seas.

We will delve into the details of how to locate the engine room and explore its inner workings, including the role of the skilled engineers and crew members who ensure smooth operations.

Additionally, we will discuss the safety measures in place and the innovative design of cruise ship engines. Get ready to appreciate the engineering marvels that drive these magnificent vessels.

Key Takeaways

- The engine room is the powerhouse of a cruise ship and houses the main engine, generator, fuel tank, pump, and control system.

- Diesel engines are commonly used in cruise ships for their power and fuel efficiency.

- Continuous monitoring and maintenance of engine performance are essential, with real-time data collected on temperature, pressure, and vital parameters.

- Safety protocols and measures, including regular safety drills, fire suppression systems, and gas detection systems, are in place to prioritize passenger well-being during the voyage.

12x50 UHD Binoculars for Adults High Powered with Upgraded Phone Adapter - Large View, Lightweight, IPX7 Waterproof, BAK4 Prism - Binoculars for Hunting Bird Watching Cruise

BINOCULARS FOR BIRD WATCHING: IBQ Binoculars with high-end lens coatings and a large field of view (5.8) with...

As an affiliate, we earn on qualifying purchases.

Understanding the Layout of a Cruise Ship

To fully comprehend the layout of a cruise ship, you must familiarize yourself with the location of the engine. Understanding ship layout is crucial for passengers who wish to explore the entire vessel.

The engine room, where the heart of the ship lies, is usually located in the lower levels towards the aft section. This area is strictly off-limits to passengers for safety reasons, but crew members are constantly working here to ensure smooth sailing.

The engine room houses the ship’s propulsion system, which powers the vessel and keeps it moving through the water. It is a complex and intricate space filled with massive engines, generators, boilers, and fuel tanks. Without this vital machinery, the ship would be immobile.

Transitioning to the subsequent section about the importance of the engine room, let’s now delve into its critical role in ensuring a safe and enjoyable cruise experience.

Adorrgon 12x42 HD Binoculars for Adults High Powered with Phone Adapter, Tripod and Tripod Adapter - Large View Binoculars with Clear Low Light Vision - Binocular for Bird Watching Cruise Travel

【Powerful 12x42 Binoculars, but Lightweight Enough, only 1.1 pounds】 Adorrgon 12x42mm binoculars deliver 367ft/1000yds large field of view....

As an affiliate, we earn on qualifying purchases.

The Importance of the Engine Room

Located deep within the vessel, the heart of a cruise ship lies in the formidable and essential engine room. This highly secure and controlled area is where all the power and propulsion systems are housed, ensuring the smooth operation of the ship. The engine room is manned by a skilled crew who are responsible for the maintenance, repair, and operation of the ship’s engines and equipment. These crew members play a vital role in ensuring the safety and efficiency of the ship. They follow strict safety measures, such as wearing protective gear and adhering to established protocols, to minimize the risk of accidents or malfunctions. Safety is of utmost importance in the engine room due to the presence of high-pressure systems and potentially hazardous materials. As we move on to locating the engine room, it is crucial to understand the significance of this vital area in the functioning of a cruise ship.

Nexiview 15x52 HD Binoculars for Adults High Powered - Large & Bright View, Lightweight, IPX7 Waterproof-Binoculars for Hunting Bird Watching Travel,Hiking, Travel, Cruise, Sports with Phone Adapter

【𝐄𝐱𝐜𝐞𝐩𝐭𝐢𝐨𝐧𝐚𝐥 𝐂𝐥𝐚𝐫𝐢𝐭𝐲 𝐁𝐢𝐧𝐨𝐜𝐮𝐥𝐚𝐫𝐬: 𝐃𝐢𝐬𝐜𝐨𝐯𝐞𝐫 𝐍𝐚𝐭𝐮𝐫𝐞 𝐋𝐢𝐤𝐞 𝐍𝐞𝐯𝐞𝐫 𝐁𝐞𝐟𝐨𝐫𝐞】Featuring premium high-transmission glass and advanced anti-reflective coatings on every air-to-glass...

As an affiliate, we earn on qualifying purchases.

Locating the Engine Room

When it comes to locating the engine room on a cruise ship, there are two key points to consider: the lower decks and the aft (back) of the ship.

The engine room is typically situated on the lower decks of the ship, as this provides a stable and secure location for the massive machinery that powers the vessel.

Specifically, it can usually be found towards the aft (back) of the ship, as this allows for easy access to the propellers and steering mechanisms.

Lower Decks

Beneath the bustling decks, you’ll find the heart of the cruise ship – the engine. Located on the lower decks, the engine room is a complex and vital part of the ship’s operation. Here are four key features of the engine room:

-

Main Engine: The main engine is the powerhouse of the ship, generating the necessary thrust to propel the vessel through the water. It consists of multiple cylinders that convert fuel into mechanical energy.

-

Auxiliary Systems: The engine room also houses various auxiliary systems that support the main engine, such as generators, air conditioning units, and water treatment systems. These systems ensure the smooth functioning of the ship’s operations.

-

Control Room: The control room is the nerve center of the engine room, where engineers monitor and control the various systems. It’s equipped with advanced technology and instruments to ensure optimal performance and safety.

-

Maintenance Area: The engine room includes a dedicated space for maintenance and repairs. Engineers regularly inspect and service the equipment to prevent any potential issues.

Transitioning to the subsequent section about the aft (back) of the ship, you can find other essential components that contribute to the ship’s overall functionality.

Aft (Back) of the Ship

As you journey towards the aft of the vessel, prepare to discover the hidden secrets that lie behind the vibrant scenes of your cruise adventure.

The layout and design of the aft section of a cruise ship are carefully planned to ensure optimal functionality and efficiency. This area is where you will find the heart of the ship, the engine room. The engine room is located towards the back of the ship, below the passenger decks. Its precise layout is designed to accommodate the massive engines that power the vessel, as well as the various systems and equipment required for the ship’s operation.

Exploring the engine room offers a fascinating glimpse into the inner workings of the ship, showcasing the intricate machinery and technology that propels the cruise ship through the vast oceans.

10x42 ED Binoculars for Adults High Powered with Phone Adapter, Waterproof Binoculars with ED Lenses, Super Bright Clear for Bird Watching, Hiking, Cruise Ship, Wildlife Viewing and Outdoor Activities

【10x42 ED Binoculars】:Three Triping 10x42 binoculars are optimized with ED glass for a sharper image, elevate your viewing...

As an affiliate, we earn on qualifying purchases.

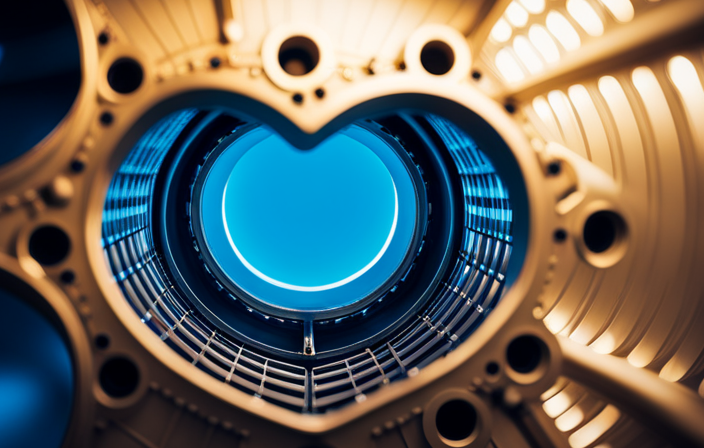

Exploring the Engine Room

When exploring the engine room, one can observe a wide array of machinery and equipment. The room is filled with massive engines, generators, pumps, and other essential components that ensure the ship’s smooth operation.

Maintenance is crucial in this space, as regular checks and repairs are necessary to keep everything in working order.

Additionally, operations in the engine room are highly coordinated, with engineers monitoring and controlling various systems to ensure optimal performance and efficiency.

Machinery and Equipment

The engine on a cruise ship is typically located in the lower decks and can be seen humming with activity. It is a complex system of machinery and equipment that ensures the ship’s propulsion and power generation.

The engine room houses various components, including the main engines, generators, boilers, and pumps.

To begin with, the main engines are responsible for propelling the ship forward. They are usually large and powerful, running on diesel or gas turbine fuel.

The generators, on the other hand, produce electricity to supply the ship’s electrical systems. These generators are essential for lighting, ventilation, and other onboard operations.

The boilers provide steam for heating and hot water, while the pumps are responsible for circulating fluids throughout the ship.

Maintenance and operations of the engine room are crucial to keep the ship running smoothly. Regular inspections, repairs, and cleaning are carried out to ensure the machinery operates optimally. This ensures the safety and efficiency of the ship’s operations.

Transitioning into the next section, proper maintenance and operations are essential for the longevity and reliability of the engine and its components.

Maintenance and Operations

To ensure smooth operations and extend the lifespan of machinery, you should prioritize regular maintenance and inspections, which can reduce the risk of costly breakdowns by up to 75%. Maintenance procedures are crucial for maintaining the efficiency and reliability of the engine on a cruise ship. This includes routine checks of the fuel, oil, and cooling systems, as well as regular cleaning and lubrication of moving parts. Emergency protocols must also be in place to handle unexpected situations and ensure the safety of passengers and crew members. These protocols involve conducting regular drills, maintaining emergency power systems, and having contingency plans for potential engine failures. By adhering to these maintenance procedures and emergency protocols, the engine on a cruise ship can operate at peak performance and minimize the risk of disruptions. Transitioning into the subsequent section, the role of engineers and crew members is vital in implementing these protocols and ensuring the smooth functioning of the engine.

The Role of Engineers and Crew Members

As an engineer on a cruise ship, my responsibilities are numerous and vital to the smooth operation of the vessel. I undergo extensive training to ensure that I am equipped with the knowledge and skills necessary to handle any maintenance or repair tasks that may arise.

Additionally, my role requires me to monitor the engine room 24/7, ensuring that all systems are running efficiently and addressing any issues that may arise immediately to avoid potential problems.

Responsibilities and Training

Engineers on a cruise ship undergo extensive training to handle the responsibilities of maintaining and operating the engine. Their main responsibility is to ensure the engine’s smooth functioning and optimal performance.

This includes regular inspections, troubleshooting, and repairs. They are trained to handle various engine components such as the fuel system, cooling system, and propulsion system. Additionally, they must be well-versed in safety protocols and emergency procedures to respond effectively in critical situations.

The training encompasses theoretical knowledge as well as hands-on experience with the ship’s specific engine model. Understanding the engine’s intricacies and being able to identify and fix issues promptly is crucial for the smooth operation and safety of the vessel.

Transitioning to the next section, monitoring and maintenance, engineers continuously monitor engine performance to detect any potential problems and perform routine maintenance to prevent breakdowns.

24/7 Monitoring and Maintenance

Keep a close eye on the performance of your vessel’s engine to ensure it runs smoothly and avoid potential breakdowns. Monitoring systems play a crucial role in this process, providing real-time data on the engine’s temperature, pressure, and other vital parameters.

By constantly monitoring these systems, you can promptly identify any anomalies or deviations from normal operating conditions, allowing for timely intervention and preventive maintenance.

Regular inspections and testing should be conducted to ensure that all components are functioning properly and that potential issues are addressed before they escalate into major problems. This includes checking the engine’s lubrication system, fuel filters, cooling system, and exhaust system.

By implementing a comprehensive preventive maintenance program and closely monitoring the engine’s performance, you can maximize its efficiency, extend its lifespan, and minimize the risk of unexpected breakdowns.

Transitioning into the subsequent section about ‘the technology behind cruise ship engines’, it is important to understand the intricate workings of these powerful machines.

The Technology Behind Cruise Ship Engines

Did you know that cruise ship engines can generate as much power as 85,000 horsepower? The technology behind cruise ship engines is fascinating and plays a crucial role in ensuring a smooth and efficient journey. Cruise ship propulsion is typically achieved using diesel engines, which are known for their high power output and fuel efficiency. These engines are usually located in the lower part of the ship, known as the engine room. The engine room is a complex and tightly organized space, housing not only the engines but also various auxiliary systems, such as generators, pumps, and fuel tanks. To give you a better idea, here is a table showcasing some of the key components found in a typical cruise ship engine room:

| Component | Purpose |

|---|---|

| Main engine | Generates propulsion power |

| Generator | Produces electricity |

| Fuel tank | Stores fuel for the engines |

| Pump | Moves fluids throughout the ship |

| Control system | Manages engine operations |

Now that you have an understanding of the technology behind cruise ship engines, let’s delve into the important topic of engine room safety measures.

Engine Room Safety Measures

Picture yourself on a grand ocean adventure, where safety is of utmost importance. To ensure your peace of mind, let’s explore the essential safety measures implemented in the heart of the vessel, where the powerful machines hum with precision and purpose.

The engine room, though a marvel of engineering, presents its fair share of hazards. Safety protocols are meticulously followed to mitigate any risks. Protective clothing, including hard hats, safety goggles, and fire-resistant suits, are mandatory for all personnel entering the engine room. Regular safety drills are conducted to ensure everyone is well-prepared for emergencies.

Fire suppression systems, such as firefighting foam and automatic sprinklers, are strategically installed throughout the engine room. Additionally, gas detection systems continuously monitor for any potential leaks. With these rigorous safety measures in place, passengers can relax and enjoy their voyage knowing that their well-being is paramount.

Moving forward, let’s delve into the exciting innovations in cruise ship engine design.

Innovations in Cruise Ship Engine Design

As you embark on your ocean adventure, imagine the thrilling advancements that have transformed the heart of these majestic vessels into a realm of innovation and efficiency. Cruise ship engine design has come a long way in recent years, with a focus on improving efficiency and sustainability. New technologies and engineering solutions have been implemented to reduce fuel consumption and emissions, making cruise ships more environmentally friendly. One example of this is the use of advanced propulsion systems, such as hybrid engines that combine traditional diesel power with electric propulsion. These systems allow for greater fuel efficiency and lower emissions. Additionally, cruise ship engine rooms now incorporate advanced monitoring and control systems to optimize performance and ensure safe operation. These innovations in cruise ship engine design are a testament to the industry’s commitment to sustainability and efficiency. Moving forward, the challenges and solutions in engine room management will be explored further.

Challenges and Solutions in Engine Room Management

Witness the mind-boggling obstacles faced in maintaining and operating the intricate machinery that powers these floating marvels. The challenges in engine maintenance on a cruise ship are numerous and require effective engine room management techniques.

One of the major challenges is the sheer size and complexity of the engine room, which houses multiple engines, generators, and auxiliary equipment. Ensuring that all systems are operating at peak performance requires constant monitoring, regular inspections, and preventive maintenance.

Additionally, the engine room is a high-risk area, with potential hazards such as fire, fuel leaks, and machinery malfunctions. Therefore, strict safety protocols and emergency response plans must be in place to protect both the crew and the ship.

Despite these challenges, with proper management and adherence to industry standards, cruise ships continue to operate smoothly, allowing passengers to appreciate the engineering marvels that make these voyages possible.

Appreciating the Engineering Marvels of a Cruise Ship

Marvel at the astonishing feats of engineering that bring these majestic floating wonders to life! Cruise ships are engineering marvels that require meticulous planning and design to operate smoothly. The engine room, located deep within the ship, is the powerhouse that propels these behemoths across vast oceans.

Here are four key elements of cruise ship engineering that contribute to their impressive performance:

-

Power Generation: Cruise ships have massive diesel engines that generate electricity to power the entire vessel, from propulsion to lighting and air conditioning.

-

Waste Management: Efficient waste management systems are crucial to maintaining the ship’s environmental footprint. Advanced technologies are employed to treat and store wastewater and solid waste.

-

Safety Systems: Cruise ships are equipped with state-of-the-art fire detection and suppression systems, ensuring the safety of passengers and crew in the event of an emergency.

-

Energy Efficiency: To reduce fuel consumption and emissions, cruise ships utilize innovative technologies like hybrid power systems, waste heat recovery, and optimized hull designs.

Appreciating the engineering marvels and overcoming the challenges in engine room management is paramount to the successful operation of these floating wonders.

Frequently Asked Questions

How many engines does a typical cruise ship have?

A typical cruise ship has multiple engines, usually numbering between 3 and 6. These engines are meticulously maintained through a comprehensive maintenance program, ensuring their optimal performance and safety. Compared to airplane engines, cruise ship engines are larger and designed for prolonged use at lower speeds.

What type of fuel do cruise ship engines use?

Cruise ship engines typically use heavy fuel oil, but there are advantages to using alternative fuels. These fuels can reduce emissions and dependence on fossil fuels. Renewable energy sources like wind and solar power can potentially power cruise ship engines, but further research and development is needed.

How much power does a cruise ship engine generate?

A cruise ship engine can generate an immense amount of power, typically measured in megawatts. Through continuous cruise ship engine maintenance and advancements in technology, innovations have allowed engines to become more efficient, reliable, and environmentally friendly.

How long does it take to build a cruise ship engine?

Building a cruise ship engine is a complex process that requires meticulous planning and skilled craftsmanship. It can take several months to complete, depending on the size and specifications. The cost varies, but maintenance is crucial to ensure optimal performance and longevity.

Are cruise ship engines environmentally friendly?

Yes, there are alternatives to traditional cruise ship engines. Extensive research is being conducted to make cruise ship engines more environmentally friendly, focusing on reducing emissions and utilizing cleaner fuel sources.

Conclusion

In conclusion, the engine room is a vital component of a cruise ship. It houses the powerful engines that propel the vessel through the water. Located deep within the ship, it requires skilled engineers and crew members to efficiently operate and maintain the engines.

With safety measures in place, the engine room is a highly regulated area. It is fascinating to note that a typical cruise ship engine can generate up to 100,000 horsepower. This is equivalent to the power of 400 cars combined. This staggering statistic showcases the impressive engineering behind these magnificent vessels.